PLASTIMIX®

Antistatic

Antistatic Masterbatches

help prevent static charge that will be generated during processing, transportation, filling or any handling of the plastic part. Static charge can result in dust accumulation or even dangerous sparking in hazardous environments.

These master batches are based on fatty acid ester type of anti static agents to neutralize the charges deposited on the surface of the polymer. By using anti static additive MB , problems caused by static charge will be reduced or eliminated. The main problems of static charge are:

Dust pick up which can gives dull appearance on surface of finish goods.

Electronic static discharge damaging electronic device.

Antistatic masterbatch works by migrating additives to the surface of the polymer. It functions usually in a molecular or multi-molecular layer and attracts water molecules from the atmosphere. The water lowers the surface resistivity from the approximate value of 10^14 – 10^15 ohms for most polymers (including styrene’s and polyolefins) to 10^11- 10^8 ohm . Normal addition levels of the 10% active content masterbatch are 3-5%.

Electrostatic charges are commonly generated by frictional contact between two materials with different susceptibilities to electron loss. One material loses electron and becomes +ve charged . The other gains electron and with them, , a -ve charge. The magnitude of the charge depends on the degree of contact and on it’s electrical properties such as : a) Dielectric constant b) Resistivity.

It also depends upon surrounding medium, moist air being more effective than dry air.

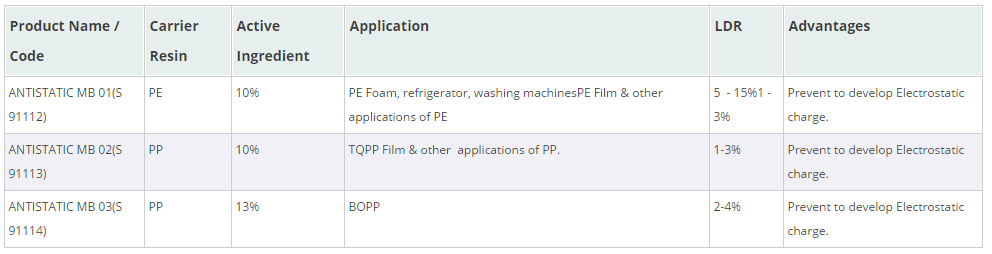

Antistatic Agent MBs offered by Sri Vasavi Pigments (P) Ltd. are